Details are critical. Missing the mark by an inch or even a few degrees of temperature can compromise the structural integrity of your asphalt. Weakness will lead to cracks and crumbling -- leaving you to return for a potentially costly repair, overlay, or new paving years earlier than typically necessary.

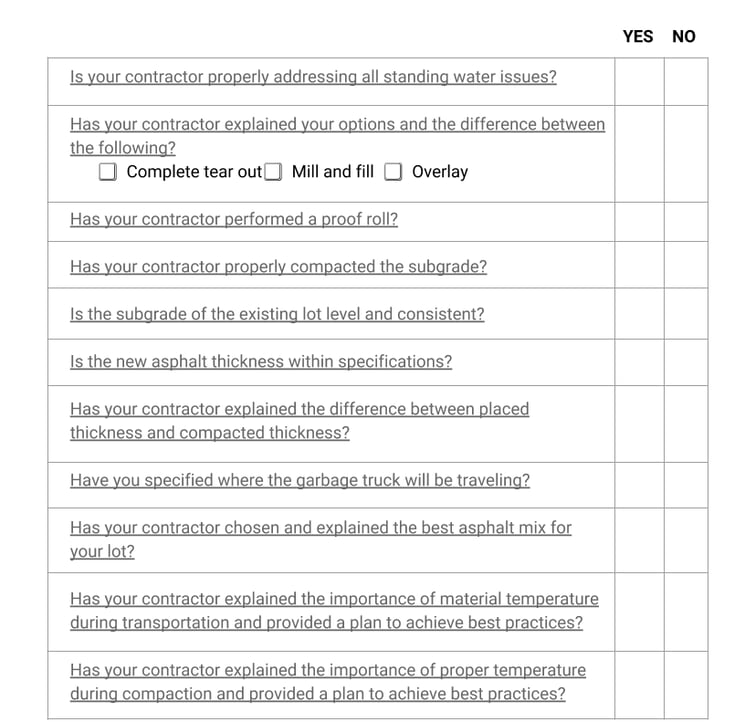

Asphalt Paving Quality Control Checklist

Here’s a checklist of 21 items to confirm with your contractor (and yourself) for a high-quality job. Each item has an explanation in the following section. Feel free to print this check list and use it as a guide during your next asphalt paving job.

-1.png?width=754&height=828&name=Asphalt%20Paving%20Quality%20Assurance%20Checklist%20Park%20Enterprise%20Construction%20(1)-1.png)

1. Is Your Contractor Properly Addressing All Standing Water Issues?

Water management systems are necessary to prevent flooding and erosion damage to your lot and surrounding landscaping. Your contractor must survey the topography for low-lying areas where water will pool and cause the most damage. From there, a storm water management system should be constructed to ensure water either flows into a clear, freely flowing catch basin with storm pipes, or a ditch or inlet.

Ask the contractor if the survey uncovered any potential problem areas and if they’ve detailed an appropriate plan of action, including precision grading and using sturdy construction aggregate in the subgrade. The solution may include retention pools, porous asphalt mixes, or rainwater harvesting.

2. Has Your Contractor Explained Your Options and the Difference Between s Complete Tear Out, Mill-and-Fill, or Overlay?

The more asphalt the better. However, you must be careful not to leave existing asphalt in place if the cracks are so bad that they will transfer to the new surface.

You have 3 options (in descending order of intensity):

- Complete tear out - Rip it up for a fresh start

- Mill-and-fill - Mill the old asphalt down to the base and lay new surface in some or all areas

- Overlay - Pave a new layer over top of the existing one

Each option has its uses and comes with its associated cost. Keep in mind, patchwork is not a permanent fix.

Do you want this quality assurance checklist emailed to you? Click here!

3. Has Your Contractor Done a Proof Roll?

Your contractor should perform an initial proof roll to make sure the foundation can support at least the weight of a fully loaded dump truck. This helps to locate weak spots and prevent asphalt failure once the lot is paved.

Ask your contractor to prove the physical strength of multiple spots along the subgrade in this manner. Any weak spots should be filled with construction aggregate stone for extra support.

4. Has Your Contractor Properly Compacted the Subgrade?

The subgrade is a platform that must solidly support a massive, uniform distribution of weight. Even a small driving surface could weigh dozens or hundreds of tons when paving is complete.

If your subgrade isn’t compacted correctly (or at all), it creates opportunity for erosion in the pavement foundation. This impacts your entire lot’s structural integrity, and can cause long-term or sudden pavement failure.

5. Is the Subgrade of the Existing Lot Level and Consistent?

If the subgrade is inconsistent, there will be less asphalt on the high areas and more on the low. Less asphalt equals less strength and durability.

Strength begins with the subgrade. The new pavement will only be as strong as the base it lies upon. To get there, the subgrade must first be completely level and consistent, which can involve stabilization acts like:

- Milling old asphalt, if necessary

- Excavating poor subgrade

- Shoring up weak subgrade with more strongly compacting dirt or construction aggregate

- Additional base rolling

- Compaction

The contractor must precisely grade the base. GPS-guided graders, which measure elevation, are most likely to achieve leveling perfection. Without precision grading, asphalt on base areas with higher elevations will be thinner and more quick to crack and fail.

6. Is the New Asphalt Thickness Within Specifications?

Your asphalt must be thick enough (strong enough) to support literal tons of weight. Here are some thickness suggestions:

- 3” of compacted asphalt thickness on 6” of aggregate stone for light-duty lots with aggregate bases

- 4” of compacted asphalt thickness on 8” of aggregate stone for heavy-duty lots with aggregate bases

These, however, are simply guidelines to follow. Many more factors must be considered before deciding an appropriate thickness.

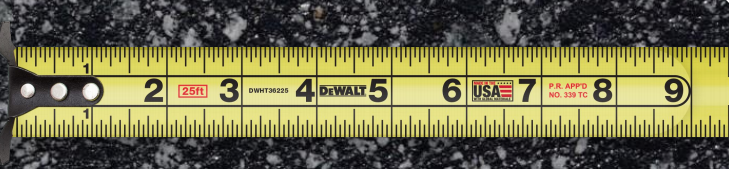

Discuss with your contractor the ideal thickness of compacted asphalt and subsurface support needed for the amount of traffic it’ll carry. At each stage of compaction (for both the subgrade and the asphalt) you can physically measure the thickness with a simple tape measure. If it doesn’t reach the levels deemed necessary, express your concern with the contractor to add more aggregate or asphalt before it’s too late.

7. Has Your Contractor Explained the Difference Between Placed Thickness and Compacted Thickness?

Asphalt will compact at a rate of .25” per 1”. For example:

- For 2” of compacted asphalt the contractor must lay 2.5”

- For 3” of compacted asphalt the contractor must lay 3.75”

- For 4” of compacted asphalt the contractor must lay 5”

Let’s say, for instance, you request 4” of asphalt to be paved and your contractor only lays 4” of uncompacted asphalt. The compacted result will be thinner and less durable, meaning it’s more likely to crack and fail in less time.

Ask your contractor to detail the plan to achieve the necessary thickness. Laying anything short of the uncompacted amount needed for ideal compaction is unacceptable.

8. Have You Specified Where the Garbage Truck Will Be Traveling?

The garbage truck is likely the heaviest load your asphalt parking lot will support on a weekly, or even daily, basis. Large amounts of weight repeatedly traveling over the same spot speeds up wear and tear in that section.

In some cases, you can simply move dumpsters around to ensure one section of the lot does not experience more wear than most others. Or, your contractor can lay more asphalt in that section to better support excess weight.

9. Has Your Contractor Explained Their Choice of Asphalt Mix for Your Lot?

Different cocktails (mixtures using different percentages of the raw asphalt oil byproduct, aggregates, and sand) perform better in different settings. Some are best for heavy duty or light duty; others compact differently.

Your contractor likely has a favorite blend. Does it meet DOT specs? Did it last long at the contractor’s previous jobs? Find out which blend your contractor recommends and why. If necessary, visit those previous jobs personally to see for yourself or ask the property owner about any quality concerns.

10. Has Your Contractor Explained the Importance of Material Temperature During Transportation?

Temperature is critical for even paving and proper compaction. Asphalt typically leaves the plant at around 325° F, at which point it’s soft and easy to compact, although the proper temperature sometimes varies by the grade of raw asphalt used. It stiffens up as it cools, making compaction more difficult. The hotter the asphalt, the easier and quicker it is to pave and finish.

Your contractor should NOT lay new asphalt pavement in cold, wet conditions. State DOTs everywhere urging paving activities to cease in periods of steady rain (unless a load of new asphalt is actively in transit from the plant).

Ask your contractor what equipment they use to insulate the asphalt and prevent temperature loss.

11. Has Your Contractor Explained the Importance of Proper Temperature During Compaction?

Asphalt must be compacted at the highest temperature possible. This is because it is easiest to compact when it reaches your site around 300° F (depending on ambient temps). More compaction means greater density.

The greater the asphalt density, the fewer pores (empty spaces) will allow water in to cause damage. If there are too many pores, your asphalt lot will crumble and fail more quickly. Generally, for every 1% increase in air voids, asphalt loses 10% of its useful life and will begin deteriorating more quickly.

There’s a proven equation for percentages of air voids in compacted paving. The industry rule of thumb is asphalt comprising between 3% and 7% air voids. If voids reach or surpass 8%, they’ll become more interconnected and allow moisture to permeate and eventually erode and break apart your pavement. However, if voids are less than 3%, your pavement won’t have enough breathing room in hot weather for expansion of asphalt binder. At 2% or below, it will be too stiff.

12. Is Your Contractor Paving to Maximize Hot Joints and Limit Cold Joints?

Joints in the asphalt inevitably fail first. Joints are the strips of asphalt where lanes meet and connect after being paved separately, which means they cool at different rates. This makes it difficult to achieve consistent compaction, adequate density, and adhesion.

Joint heaters can be used to create better adhesion by limiting low density, permeability, and segregation.

Four different conditions can negatively or positively affect the quality of your asphalt parking lot at the time the asphalt is placed:

- Air temperature

- Base temperature

- Hot mix asphalt temperature

- Wind velocity

A joint heater can preheat the asphalt in the cold lane just before laying a fresh lane of hot asphalt. The ideal range for reheating cold joints is roughly between 210° F and 250° F.

Again, your contractor must have the right transport equipment to keep the raw asphalt at the right temperature. Discuss plans to lay the asphalt correctly given the weather conditions present that day and the distance traveled from the plant.

13. Is Your Contractor Paving in a Way that Eliminates Roller Marks?

Roller marks, or roller tracking, are visible creases in the asphalt. They’re a clear indicator the compaction process was not completed or that temperatures weren’t adequately factored.

Whether your contractor uses a vibratory static roller or a pneumatic tire roller, residual roller marks or creases may be left in your pavement if:

- There are composition issues with the asphalt mix

- Asphalt temperature isn’t within proper range

- Roller timing was inaccurate

- Not enough roller passes were made

Your contractor should plan for an appropriate number of rollers (see number 15) on site to complete an ideal number of passes before cooling. The finish roller typically can eliminate these marks when the hot mix has cooled to between 160° F and 140° F. In certain environmental conditions, pneumatic tire rollers may effectively remove these creases.

14. Has Your Contractor Explained and Accounted for Lift Thickness in Each Layer?

Lift thickness is the amount of loose asphalt material first placed before compaction begins with a mechanical roller. As lift thickness goes up, interconnected air voids are less likely to span the entire asphalt depth, which decreases permeability. Less permeability equals less chance for water to infiltrate and begin its destructive processes.

The general guideline for maximum lift thickness is 6” on existing asphalt and 8”-12” on clay and aggregate. Sometimes, commercial parking lot lifts could be 4” or less because when smaller rollers are used.

Compaction is critical to all phases of asphalt paving. If lift thickness is too great, the rolling process will bridge the material beneath and compact only the top layer, almost certainly causing deterioration problems sooner

15. Did Your Contractor Give You Notice of How Much Equipment and Workers to Expect On-Site?

Your contractor should notify you of how many pieces of equipment and people will be taking up space on the site. Expect to have equipment sitting on your lot for the duration of the project.

Work with your contractor to determine:

- How much equipment and how many people will be on site at any given time

- How long you can expect the project to take

- Where equipment will be stored when not in use

Do you want this quality assurance checklist emailed to you?Click here!

16. Will Your Contractor Fill Necessary Cold Joints with Rubberized Asphalt Before Completion?

Cold joints can’t be avoided in asphalt paving, as contractors can usually pave only 1 lane at a time. They occur where fresh, hot asphalt meets existing pavement that has already cooled. Joints are the weakest spots in your parking lot. They’re most likely to absorb water and expand and contract with cold and hot temperatures. All joints that meet existing concrete or asphalt should be filled with rubberized crack filler before the contractor leaves your site.

Sealing parking lots is essential within 2-5 years to enhance the aesthetic appeal and more importantly to prevent water from seeping in to do damage. At cold joints, this is even more important.

Furthermore, your contractor should be careful addressing compaction of sides or ends of asphalt that are unconfined - for example, at the parking lot’s edges. The unconfined edge can be more difficult to compact as it spreads sideways more easily and loses density. These places will generally have more air voids that lead to the asphalt’s gradual (or not so gradual) deterioration.

Ask your contractor how crews will combat temperature disparities and low density at joints.

17. Do You Have a Plan to Direct Customers Around the Fresh Pavement?

This can be a tricky balancing act. You want your business to remain open, but your lot needs time to fully cool and compact. This typically takes 24 hours, or longer in very hot weather.

To keep business flowing, try:

- Scheduling construction on off days or evening hours (your contractor should accommodate your schedule)

- Scheduling construction in stages, if you have portions of a current parking lot that still could be used

- Planning routes from alternate parking areas to your entrance(s)

18. Did You Request & Receive Asphalt Tickets?

The general guideline is 2 tons of asphalt per cubic yard. Request documentation of how much asphalt was taken from the plant and used at your site. This helps you keep track of how much asphalt you paid for and how much was actually laid on your lot.

19. Have You Checked Your Contractor’s Previous Work References?

Cutting corners is an easy way for less reputable contractors to save on initial costs and skim more profit off the top. Luckily, this can be prevented if you do your homework.

Ask the contractor for a list of previous jobs and call the property owners involved. If possible, visit sites of their past work to see it for yourself.

20. Has Your Contractor’s Equipment Been Inspected for Proper Operation to Limit Breakdowns on the Job?

Depending on the scope, a paving project could feature multiple pieces of heavy machinery on the site. These tools (and others) must be inspected to ensure safety for the operator, fellow construction staffers, and the property. Plus, poor-quality equipment can mean a poor-quality paving job.

State DOTs generally mandate a thorough self-inspection of all commercial road and construction vehicles annually. Request proof of inspection to make sure no one gets injured on your property and you’re getting the best quality workmanship possible.

21. Does Your Contractor Offer a Warranty?

A warranty protects your investment if your lot fails early due to an error by your contractor. The agreement could also include seal-coating, which renews the surface of the lot to make your entire lot last longer.

Some general contractors don’t offer extended warranties. An experienced contractor will adhere to its own quality standards and still offer a warranty on workmanship under normal use. To you, this is a guarantee that the contractor will offer a solution if something doesn’t go as planned the first time.

While you should expect nothing short of perfection on the first shot, discuss warranty options with your contractor to protect your business/organization and your lot from unavoidable oversights and human errors.

How can we put those elements to work for you? Let’s build something beautiful together. Get a free paving estimate here or contact us with any other questions.